Go Into URL |

| |

| |

| |

|

Contact Us |

| WELCOME TO CONTACT US! |

|

|

ABOUT US |

| |

Import Bearing Brand >> FAG Product List

|

Deep groove ball bearings

Deep groove ball bearings, the structure is simple, use convenient to maintain. Mainly used to bear radial load, also can withstand the axial load, when bearing radial clearance increase, with Angle contact ball bearing performance and can withstand the larger axial load. These bearings are small friction coefficient, extreme high speed, size range and forms a variety. Solid and durable, strong commonality and low noise, can be in the running speed operation and easy to install. Single deep groove ball bearings otherwise sealed type design, can no more lubrication and no maintenance. Single belt loaded ball gap and double row ball bearings, applies to heavy work conditions.

Deep groove ball bearings, the structure is simple, use convenient to maintain. Mainly used to bear radial load, also can withstand the axial load, when bearing radial clearance increase, with Angle contact ball bearing performance and can withstand the larger axial load. These bearings are small friction coefficient, extreme high speed, size range and forms a variety. Solid and durable, strong commonality and low noise, can be in the running speed operation and easy to install. Single deep groove ball bearings otherwise sealed type design, can no more lubrication and no maintenance. Single belt loaded ball gap and double row ball bearings, applies to heavy work conditions.

|

|

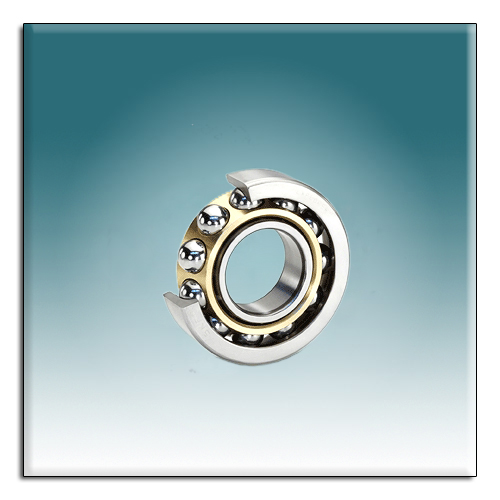

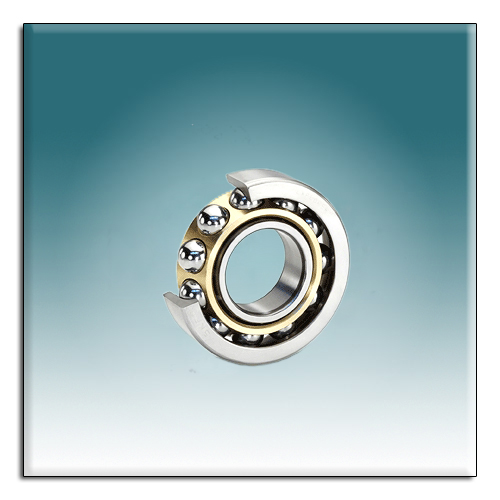

Angular contact ball bearings

Angle contact ball bearing can bear radial load and axial load. Can work under high speed. Contact Angle, the greater the axial bearing capacity is higher. High precision and high speed bearings are usually take 15 degrees contact Angle. In the axial force, can increase the contact Angle. Single Angle contact ball bearing can only carry axial load in one direction, in radial load, will cause additional axial force. And only limit or shell in a direction of the axial displacement. If double installation, make a pair of bearings, the inner surface is wide wide, narrow end face with narrow face. This can avoid causing additional axial force, but also can make axis in two directions or restrictions on axial clearance range.

Angle contact ball bearing can bear radial load and axial load. Can work under high speed. Contact Angle, the greater the axial bearing capacity is higher. High precision and high speed bearings are usually take 15 degrees contact Angle. In the axial force, can increase the contact Angle. Single Angle contact ball bearing can only carry axial load in one direction, in radial load, will cause additional axial force. And only limit or shell in a direction of the axial displacement. If double installation, make a pair of bearings, the inner surface is wide wide, narrow end face with narrow face. This can avoid causing additional axial force, but also can make axis in two directions or restrictions on axial clearance range.

|

|

Thrust ball bearings

Thrust ball bearings are separated type bearings, according to its structure is divided into i.e.one-way thrust ball and two-way thrust ball bearings. One-way thrust ball bearings can withstand a direction of axial load, two-way thrust ball bearings can withstand two-way axial load. Two-way thrust ball bearing and axis of circle. Seat ring installation, the bearing surface angled self-aligning performance, can reduce the influence of installation error. Thrust ball bearings are mainly applied in automobile, machine, etc.

Thrust ball bearings are separated type bearings, according to its structure is divided into i.e.one-way thrust ball and two-way thrust ball bearings. One-way thrust ball bearings can withstand a direction of axial load, two-way thrust ball bearings can withstand two-way axial load. Two-way thrust ball bearing and axis of circle. Seat ring installation, the bearing surface angled self-aligning performance, can reduce the influence of installation error. Thrust ball bearings are mainly applied in automobile, machine, etc.

|

|

Double row tapered roller bearings

Double row circular cone roller bearings, the bearing a outer circle of inner two, two inner circle is a circle between every lap, change the thickness, clearance adjustment radial and axial load, two-way in bearing clearance limit or within the scope of the axial displacement double shell. Commonly used to requirement of thin-walled bearing spindle of machine, steel rolling and printing machinery of roller, etc.

Double row circular cone roller bearings, the bearing a outer circle of inner two, two inner circle is a circle between every lap, change the thickness, clearance adjustment radial and axial load, two-way in bearing clearance limit or within the scope of the axial displacement double shell. Commonly used to requirement of thin-walled bearing spindle of machine, steel rolling and printing machinery of roller, etc.

|

|

Single Row Tapered Roller Bearings

Taper roller bearings are usually separated type, namely the belt roller and maintains a component within the circle of inner cone circles with conical outer (components can separate inner). Taper roller bearings by main bear radial primarily diameter, axial load. Bearing capacity depends on the outermost groove Angle, the bearing capacity of the larger Angle. Taper roller bearings are widely used in automobiles, rolling mill, mining, metallurgical, plastic machinery, etc.

Taper roller bearings are usually separated type, namely the belt roller and maintains a component within the circle of inner cone circles with conical outer (components can separate inner). Taper roller bearings by main bear radial primarily diameter, axial load. Bearing capacity depends on the outermost groove Angle, the bearing capacity of the larger Angle. Taper roller bearings are widely used in automobiles, rolling mill, mining, metallurgical, plastic machinery, etc.

|

|

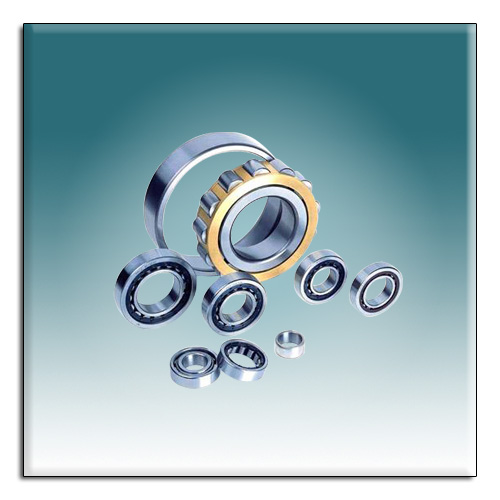

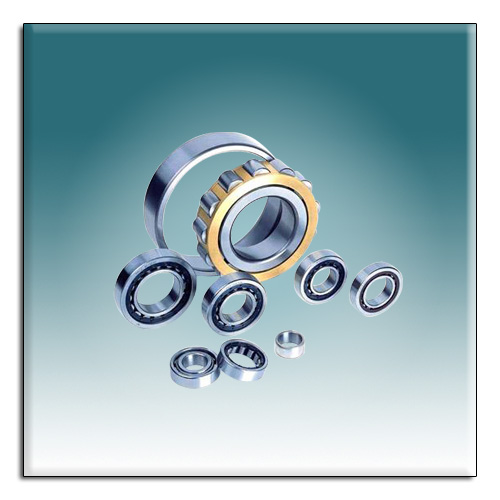

Short cylindrical roller bearing

Short cylindrical roller bearing/cylindrical roller bearing belong to precision bearing, precise sorting by shaft circle of roller, by keeping raised edge lead frame, the roller and guide shaft circles, but with another bearing collar separation, belongs to the separable bearing. These bearings installation, remove more convenient, especially when asked to inner and outer and axis, shell is made more show its advantage when combined, Such bearing only commonly used to bear radial load, only the inner and outer raised edge all takes the bearings can withstand small constant axial load or bigger intermittent axial load, The same size and shape of the other bearing, compared with high load, such bearing the noise and high speed characteristics, very applicable and all kinds of precision machinery and mining mill machinery. But with such bearing with axes, and roller and other related parts need precision processing and into.

Short cylindrical roller bearing/cylindrical roller bearing belong to precision bearing, precise sorting by shaft circle of roller, by keeping raised edge lead frame, the roller and guide shaft circles, but with another bearing collar separation, belongs to the separable bearing. These bearings installation, remove more convenient, especially when asked to inner and outer and axis, shell is made more show its advantage when combined, Such bearing only commonly used to bear radial load, only the inner and outer raised edge all takes the bearings can withstand small constant axial load or bigger intermittent axial load, The same size and shape of the other bearing, compared with high load, such bearing the noise and high speed characteristics, very applicable and all kinds of precision machinery and mining mill machinery. But with such bearing with axes, and roller and other related parts need precision processing and into.

|

|

Needle bearing

Needle contour surface in recent tip-to-face place slightly contraction. Needle with groove line contact modified results can avoid to produce destructive effect-edge stress. Supporting needle roller bearings is thick wall outside, high-temperature high nitrogen quenching, high precision separation of the roller by high rigidity of outer ring, using linear guide raised edge roller can direct contact, rolling path, and can be easily turn bear tremendous load. To remove the stress, supporting roller adopts the outer surface design, curve roller with single and double seal, not with seals, belt sealing etc various specifications. With seals storage space, provide grease lubrication, lithium base fat permanent and extend lubrication interval. Sealing material for belt skeleton buna n or ST12, its operating temperature range ° C for - 30 ° C to + 100 ° C or - 30 ° C to + 180. Dense mounting type curve roller can withstand heavier load and high performance of strong operation. No, no RSTO invading.this raised edge circle of inner supporting roller

Needle bearings equipped with fine and long roller (roller length is 3 ~ 10 times the diameter of the diameter of general is not more than 5mm), therefore radial structure.when their diameter and load capacity and other types of bearing outside diameter diam-eter, minimum, especially suitable for radial installation limited size of supporting results. According to use different occasions, can choose no inner ring bearings or needle and maintains a module, right now and bearing surface and match the shaft neck housing holes surface directly as the inner and external rolling bearing surface, to guarantee load capacity and operating performance and bearing the same with rings, shaft or housing holes groove surface hardness, machining precision and surface quality shall be the groove with bearing collar comparable. These bearings can only bear radial load.

Needle contour surface in recent tip-to-face place slightly contraction. Needle with groove line contact modified results can avoid to produce destructive effect-edge stress. Supporting needle roller bearings is thick wall outside, high-temperature high nitrogen quenching, high precision separation of the roller by high rigidity of outer ring, using linear guide raised edge roller can direct contact, rolling path, and can be easily turn bear tremendous load. To remove the stress, supporting roller adopts the outer surface design, curve roller with single and double seal, not with seals, belt sealing etc various specifications. With seals storage space, provide grease lubrication, lithium base fat permanent and extend lubrication interval. Sealing material for belt skeleton buna n or ST12, its operating temperature range ° C for - 30 ° C to + 100 ° C or - 30 ° C to + 180. Dense mounting type curve roller can withstand heavier load and high performance of strong operation. No, no RSTO invading.this raised edge circle of inner supporting roller

Needle bearings equipped with fine and long roller (roller length is 3 ~ 10 times the diameter of the diameter of general is not more than 5mm), therefore radial structure.when their diameter and load capacity and other types of bearing outside diameter diam-eter, minimum, especially suitable for radial installation limited size of supporting results. According to use different occasions, can choose no inner ring bearings or needle and maintains a module, right now and bearing surface and match the shaft neck housing holes surface directly as the inner and external rolling bearing surface, to guarantee load capacity and operating performance and bearing the same with rings, shaft or housing holes groove surface hardness, machining precision and surface quality shall be the groove with bearing collar comparable. These bearings can only bear radial load.

|

|

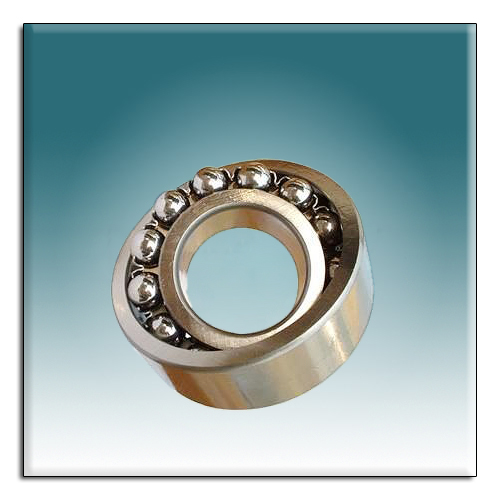

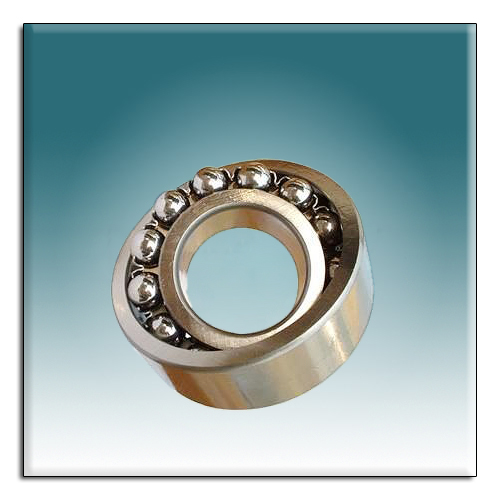

Self-aligning ball bearings

Self-aligning ball bearings have cylindrical or tapered and retainers two kinds of structure, keep the frame made of steel sheet or synthetic resins. Its characteristic is outer ring groove is spherical shape, with the nature of mind, can automatically adjustable to compensate concentricity and deflection errors, but inside and outer relative gradient must not exceed 3 degrees. Self-aligning ball bearing structure forms: take dust cover and with seals deep groove ball bearing assembly has fill in the right amount of grease, before the installation, should not be heating don‘t cleaned, use process need not lubrication, adapt to the operating temperature - 30 + 120 ℃ to ℃ between.

Because of its with two columns ball and in the outer wall-climbing groove, self-aligning ball bearings can automatically adjustable heart and can withstand the axes and bearing the Angle between the error, suitable for easy to appear the torsion shaft and wrong working conditions. The cylindrical or tapered and retainers two kinds of structure, keep the frame made of steel sheet or synthetic resins. Self-aligning ball bearings rolling bearings of friction is all in the lowest, so even at high speed circumstance, still only with smaller temperature.

Suitable for precision instruments, low noise motor, automobiles, motorcycles and general machinery, etc, is the mechanical industry the most widely used type bearings.

Self-aligning ball bearings have cylindrical or tapered and retainers two kinds of structure, keep the frame made of steel sheet or synthetic resins. Its characteristic is outer ring groove is spherical shape, with the nature of mind, can automatically adjustable to compensate concentricity and deflection errors, but inside and outer relative gradient must not exceed 3 degrees. Self-aligning ball bearing structure forms: take dust cover and with seals deep groove ball bearing assembly has fill in the right amount of grease, before the installation, should not be heating don‘t cleaned, use process need not lubrication, adapt to the operating temperature - 30 + 120 ℃ to ℃ between.

Because of its with two columns ball and in the outer wall-climbing groove, self-aligning ball bearings can automatically adjustable heart and can withstand the axes and bearing the Angle between the error, suitable for easy to appear the torsion shaft and wrong working conditions. The cylindrical or tapered and retainers two kinds of structure, keep the frame made of steel sheet or synthetic resins. Self-aligning ball bearings rolling bearings of friction is all in the lowest, so even at high speed circumstance, still only with smaller temperature.

Suitable for precision instruments, low noise motor, automobiles, motorcycles and general machinery, etc, is the mechanical industry the most widely used type bearings.

|

|

Spherical bearing outside

The component of the spherical surface bearing outer ring has spherical diameter of bearings, and the concave spherical inner hole bearing suitably, have, suitable for automatically adjustable cardiac function, flexibility larger rigid sent general axis. The bearing with seals at both closely, can prevent sewage invasion. In the factory apply already loaded into the lubricant, before the installation, do not need to clean. In allowing the lubrication period, without adding lubricant. Bearing inner circle the top side of the projection on the axle wire screws, allowed strong axial load not exceed 20% of the dynamic load.

The component of the spherical surface bearing outer ring has spherical diameter of bearings, and the concave spherical inner hole bearing suitably, have, suitable for automatically adjustable cardiac function, flexibility larger rigid sent general axis. The bearing with seals at both closely, can prevent sewage invasion. In the factory apply already loaded into the lubricant, before the installation, do not need to clean. In allowing the lubrication period, without adding lubricant. Bearing inner circle the top side of the projection on the axle wire screws, allowed strong axial load not exceed 20% of the dynamic load.

|

|

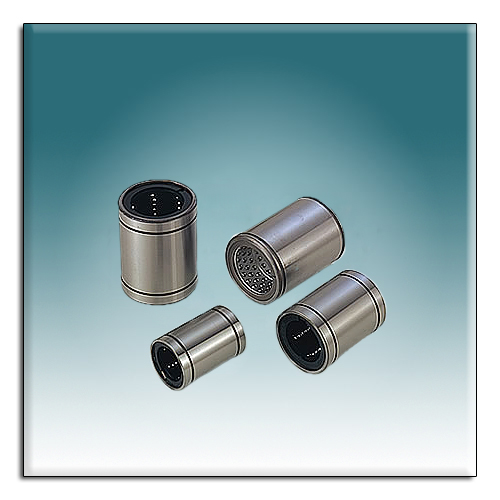

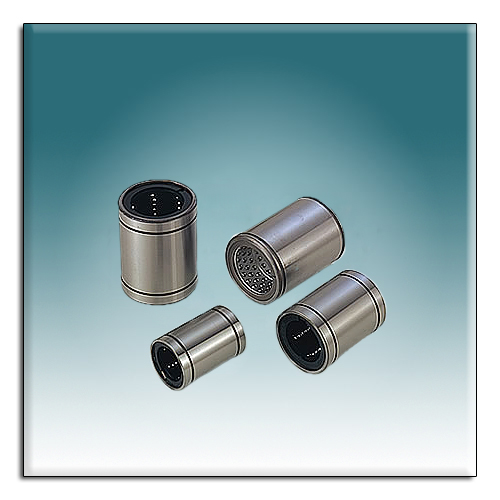

Linear bearing

Linear bearing is a kind of low cost production of linear motion system, for unlimited travel and cylindrical shaft with the use of. Because the bearing balls and shaft in point contact, the use of small load. Ball with a minimum friction resistance to the rotation, which can obtain high precision and smooth motion. Linear bearings are widely used in electronic equipment, Rally test machine and digital 3D coordinate measuring equipment, precision equipment, as well as the multi axis machine, punching machine, grinding machine tools, automatic cutting machine, printer, card sorting machine, food packing machine and other industrial machinery sliding parts.

Linear bearing is a kind of low cost production of linear motion system, for unlimited travel and cylindrical shaft with the use of. Because the bearing balls and shaft in point contact, the use of small load. Ball with a minimum friction resistance to the rotation, which can obtain high precision and smooth motion. Linear bearings are widely used in electronic equipment, Rally test machine and digital 3D coordinate measuring equipment, precision equipment, as well as the multi axis machine, punching machine, grinding machine tools, automatic cutting machine, printer, card sorting machine, food packing machine and other industrial machinery sliding parts.

|

|

|

|

|

|