Go Into URL |

| |

| |

| |

|

Contact Us |

| WELCOME TO CONTACT US! |

|

|

ABOUT US |

| |

Import Bearing Brand >> NSK Product List

|

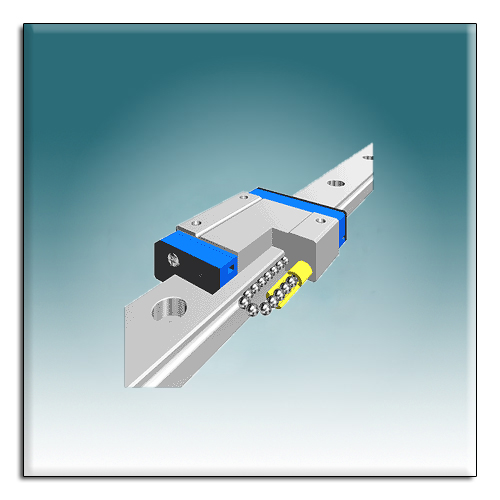

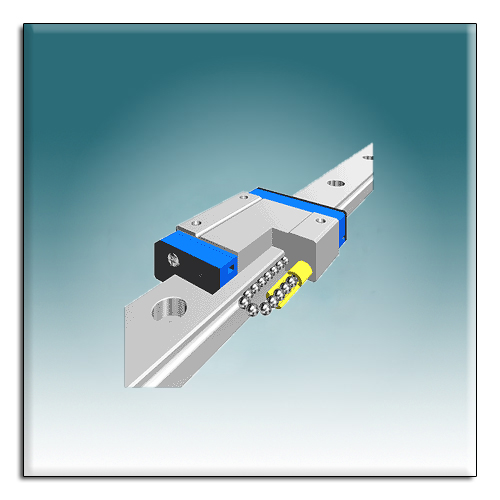

Linear Guide

Also known as linear guide rail, linear rails, linear slide, linear reciprocating motion for the occasion, with a higher rating than the linear bearing load, and can afford a certain torque, high load in the case of high precision linear motion. Linear bearings is mainly used in more automated machinery, such as machine tools imported from Germany, paper bowl machine, laser welding machines, etc., of course, linear bearings and linear axes are used for matching. As the linear guide is mainly used in relatively high precision mechanical structure. Sliding fast - so that movement into a straight line from the curve.

Also known as linear guide rail, linear rails, linear slide, linear reciprocating motion for the occasion, with a higher rating than the linear bearing load, and can afford a certain torque, high load in the case of high precision linear motion. Linear bearings is mainly used in more automated machinery, such as machine tools imported from Germany, paper bowl machine, laser welding machines, etc., of course, linear bearings and linear axes are used for matching. As the linear guide is mainly used in relatively high precision mechanical structure. Sliding fast - so that movement into a straight line from the curve.

|

|

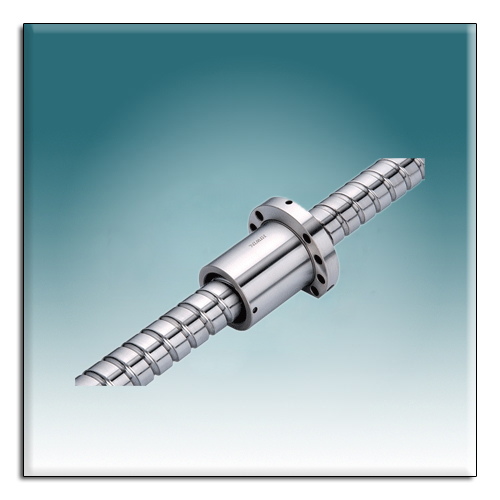

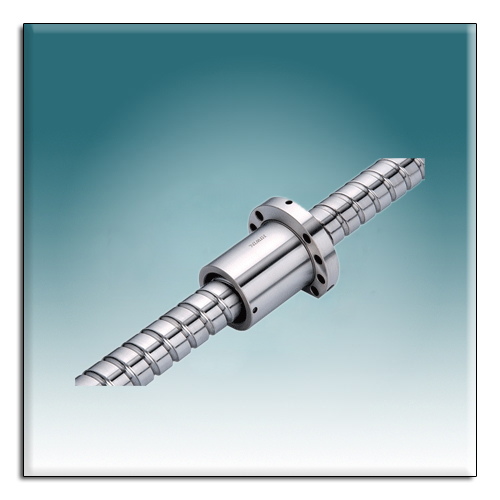

Screw Guide

Guide (daogui) guide rail: metal or other material slot or ridge, affordable, fixed, mobile device or devices to guide and to reduce the friction of a device. Longitudinal groove on the track surface or ridge, for guidance, fixed machine parts, special equipment, instruments.

Guide the application in our daily life is also very common, such as the sliding doors slide worse, the train tracks, all of which guide the specific application.

Guide (daogui) guide rail: metal or other material slot or ridge, affordable, fixed, mobile device or devices to guide and to reduce the friction of a device. Longitudinal groove on the track surface or ridge, for guidance, fixed machine parts, special equipment, instruments.

Guide the application in our daily life is also very common, such as the sliding doors slide worse, the train tracks, all of which guide the specific application.

|

|

Linear Bearings

Linear Bearings is a low-cost production of linear motion system for unlimited use with stroke and the cylinder axis. As the ball bearing point contact with the shaft was, so use a small load. With minimal friction resistance ball rotation, so that it can achieve high smooth movement.

Linear bearings are widely used in electronic equipment, tensile testing machine and digital three-dimensional coordinate measuring equipment, precision equipment, and multi-axis machine, punching machine, tool grinder, automatic gas cutting machine, printer, card sorting machine, food packing machines and other industrial machinery moving components.

Linear Bearings is a low-cost production of linear motion system for unlimited use with stroke and the cylinder axis. As the ball bearing point contact with the shaft was, so use a small load. With minimal friction resistance ball rotation, so that it can achieve high smooth movement.

Linear bearings are widely used in electronic equipment, tensile testing machine and digital three-dimensional coordinate measuring equipment, precision equipment, and multi-axis machine, punching machine, tool grinder, automatic gas cutting machine, printer, card sorting machine, food packing machines and other industrial machinery moving components.

|

|

Linear guide radiation

A compact, versatile convergence of micro linear guides, including micro-guide, mini slide, ball, back to the device and cage, with the micro-slide on the rail of the section shape and micro-phase adaptation of the groove, the groove on both sides and both sides of each mini-guide with a row of mutually supporting roller bear the load of the ball set in the groove, the micro-slide set up in the mini-guide through the ball along the mini-guide on the axial movement can be used to turn the ball back to the device fixed at both ends of the slider in the micro, mini slide, and back to the device by maintaining a fixed frame. The model is designed with two rows of Gothic double circular groove, installation, small size, high precision, been used in light load situations. It is particularly suitable for measuring equipment, computer embroidery machine, precision engraving machinery, electrical machinery, medical equipment and so on, has great practical value and market prospects.

A compact, versatile convergence of micro linear guides, including micro-guide, mini slide, ball, back to the device and cage, with the micro-slide on the rail of the section shape and micro-phase adaptation of the groove, the groove on both sides and both sides of each mini-guide with a row of mutually supporting roller bear the load of the ball set in the groove, the micro-slide set up in the mini-guide through the ball along the mini-guide on the axial movement can be used to turn the ball back to the device fixed at both ends of the slider in the micro, mini slide, and back to the device by maintaining a fixed frame. The model is designed with two rows of Gothic double circular groove, installation, small size, high precision, been used in light load situations. It is particularly suitable for measuring equipment, computer embroidery machine, precision engraving machinery, electrical machinery, medical equipment and so on, has great practical value and market prospects.

|

|

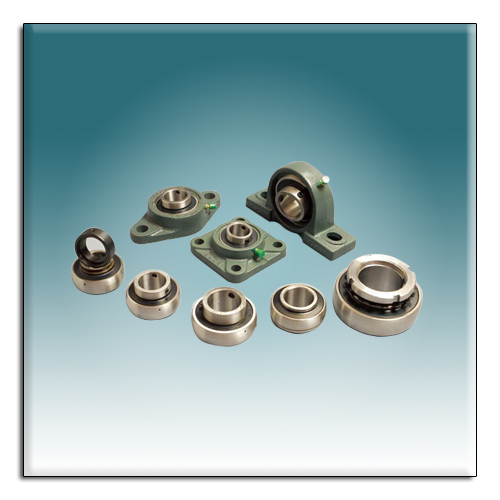

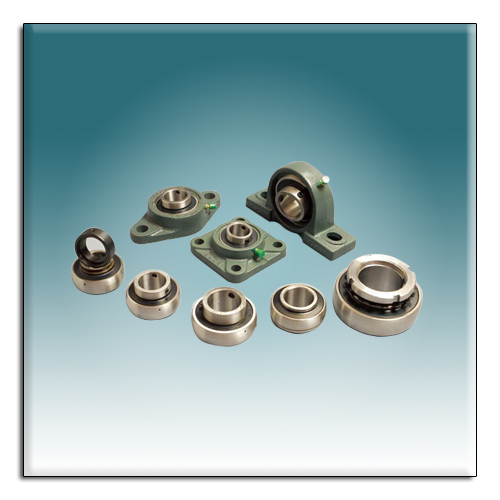

Spherical Bearings

The species has a spherical bearing outer diameter, and concave spherical bearing bore match, with auto-aligning feature for poor rigidity, disturbance greater degree of communication axis.

This kind of bearing on both sides with a ring, can close to prevent dirt intrusion. Mounted at the factory the right amount of lubricant before installation without washing. Lubrication period allowed without the addition of lubricant. Bearing inner ring on the top end of wire protruding screw in the axis solid, allow the axial load does not exceed dynamic load rating of 20%.

The species has a spherical bearing outer diameter, and concave spherical bearing bore match, with auto-aligning feature for poor rigidity, disturbance greater degree of communication axis.

This kind of bearing on both sides with a ring, can close to prevent dirt intrusion. Mounted at the factory the right amount of lubricant before installation without washing. Lubrication period allowed without the addition of lubricant. Bearing inner ring on the top end of wire protruding screw in the axis solid, allow the axial load does not exceed dynamic load rating of 20%.

|

|

Deep groove ball bearings

Deep groove ball bearings, the structure is simple, use convenient to maintain. Mainly used to bear radial load, also can withstand the axial load, when bearing radial clearance increase, with Angle contact ball bearing performance and can withstand the larger axial load. These bearings are small friction coefficient, extreme high speed, size range and forms a variety. Solid and durable, strong commonality and low noise, can be in the running speed operation and easy to install. Single deep groove ball bearings otherwise sealed type design, can no more lubrication and no maintenance. Single belt loaded ball gap and double row ball bearings, applies to heavy work conditions.

Deep groove ball bearing main bear radial load, also can withstand a certain amount of axial load. These bearings are brasive coefficient, extreme high speed, size range and forms a variety. Suitable for precision instruments, low noise motor, automobiles, motorcycles and general machinery, etc, is the mechanical industry the most widely used type bearings.

Deep groove ball bearings, the structure is simple, use convenient to maintain. Mainly used to bear radial load, also can withstand the axial load, when bearing radial clearance increase, with Angle contact ball bearing performance and can withstand the larger axial load. These bearings are small friction coefficient, extreme high speed, size range and forms a variety. Solid and durable, strong commonality and low noise, can be in the running speed operation and easy to install. Single deep groove ball bearings otherwise sealed type design, can no more lubrication and no maintenance. Single belt loaded ball gap and double row ball bearings, applies to heavy work conditions.

Deep groove ball bearing main bear radial load, also can withstand a certain amount of axial load. These bearings are brasive coefficient, extreme high speed, size range and forms a variety. Suitable for precision instruments, low noise motor, automobiles, motorcycles and general machinery, etc, is the mechanical industry the most widely used type bearings.

|

|

Self-aligning roller bearings

Self-aligning roller bearings, outer ring groove is spherical shape, with the nature of mind, can automatically adjustable to compensate concentricity and deflection errors, but inside and outer relative gradient must not exceed 3 degrees.

1. The outer ring groove is spherical part, bearing have internal self-aligning performance, in order to adapt to the relative shaft to seat hole righthanders.

2. Can bear radial heavy load and impact load, also can withstand the two-way axial load.

3. Of these bearings can restrict shaft or shell of axial displacement in bearing axial clearance range.

4. Such bearing structure principles and characteristics and self-aligning ball bearing the same, in load capacity and limit speed permission of the mutual substitution.

5. Taper hole bearing through the use of fasteners or refund discharge can facilitate axis loading fold.

Suitable for precision instruments, low noise motor, automobiles, motorcycles and general machinery, etc, is the mechanical industry the most widely used type bearings.

Self-aligning roller bearings, outer ring groove is spherical shape, with the nature of mind, can automatically adjustable to compensate concentricity and deflection errors, but inside and outer relative gradient must not exceed 3 degrees.

1. The outer ring groove is spherical part, bearing have internal self-aligning performance, in order to adapt to the relative shaft to seat hole righthanders.

2. Can bear radial heavy load and impact load, also can withstand the two-way axial load.

3. Of these bearings can restrict shaft or shell of axial displacement in bearing axial clearance range.

4. Such bearing structure principles and characteristics and self-aligning ball bearing the same, in load capacity and limit speed permission of the mutual substitution.

5. Taper hole bearing through the use of fasteners or refund discharge can facilitate axis loading fold.

Suitable for precision instruments, low noise motor, automobiles, motorcycles and general machinery, etc, is the mechanical industry the most widely used type bearings.

|

|

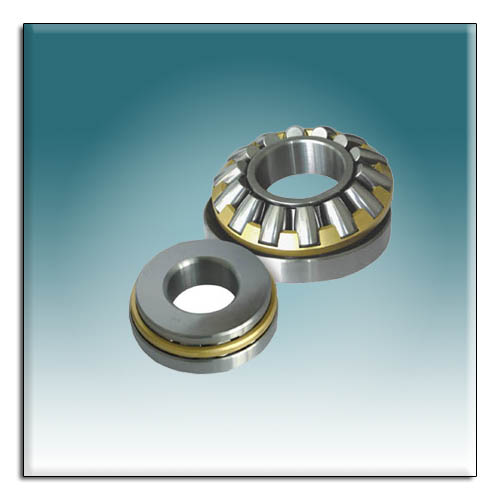

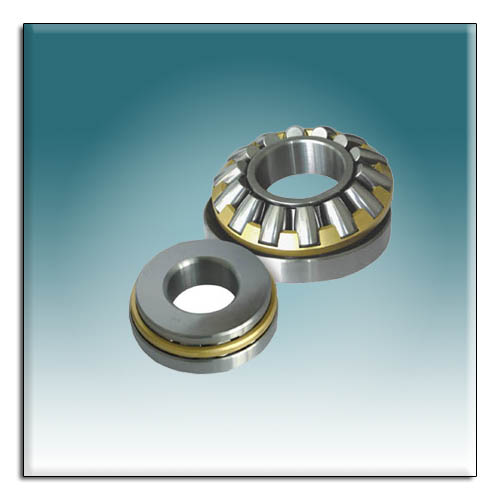

Thrust roller bearings

Thrust roller bearings are used to carry axial load primarily axial and radial combined load, but radial load must not exceed axial load, etc. Compared with other thrust roller bearings, these bearings friction factor is lower, high speed, and has the self-aligning performance. 29,000 type bearings stick for the unsymmetrical spherical roller, which can reduce roller with groove in the work relative sliding, and roller long, large in diameter, and roller number, load capacity, high, usually by oil lubrication, individual low-speed circumstance is usable and grease. In design selection, should first selection, 80,000 type cylindrical roller thrust bearing, 90,000 type thrust tapered roller bearing and AXK type thrust needle bearing, can withstand one-way axial load, it than thrust ball bearing axial load capacity is much bigger, and rigid big, take up the axial small space. Cylindrical roller thrust bearing and thrust needle bearing applies to speed occasions with low tapered roller bearings, thrust speed slightly above cylindrical roller thrust bearing.

Thrust roller bearings are used to carry axial load primarily axial and radial combined load, but radial load must not exceed axial load, etc. Compared with other thrust roller bearings, these bearings friction factor is lower, high speed, and has the self-aligning performance. 29,000 type bearings stick for the unsymmetrical spherical roller, which can reduce roller with groove in the work relative sliding, and roller long, large in diameter, and roller number, load capacity, high, usually by oil lubrication, individual low-speed circumstance is usable and grease. In design selection, should first selection, 80,000 type cylindrical roller thrust bearing, 90,000 type thrust tapered roller bearing and AXK type thrust needle bearing, can withstand one-way axial load, it than thrust ball bearing axial load capacity is much bigger, and rigid big, take up the axial small space. Cylindrical roller thrust bearing and thrust needle bearing applies to speed occasions with low tapered roller bearings, thrust speed slightly above cylindrical roller thrust bearing.

|

|

Taper roller bearings

Taper roller bearings which mainly bear with radial primarily diameter, the axial union load. Bearing outer ring rolling bearing capacity depends on the way Angle, the larger Angle bearing capacity is bigger. These bearings are of separated type bearings, according to the roller bearing in the column number to be mounted, double row and four row circular cone roller bearings. Single tapered roller bearing clearance to users in when installation, adjustment, Double row and four row circular cone roller bearings clearance already in product factory according to user requirements are given, not the user to resize.

Taper roller bearings taper inner ring and outer ring have groove, tapered roller are arranged in between. All taper surface projection lines are the same point in bearing axis reunion. This design makes tapered roller bearings specially suitable for composite (bear) radial and axial load. Bearing axial load ability is mostly decided by the contact Angle is alpha, Alpha greater perspective, axial load capacity is higher. Angle size by calculating coefficient e to say, E is, the contact Angle is, the bigger the bearing axial load applicability is greater.

Taper roller bearings are usually separated type, namely the belt roller and maintains a module of the inner ring of conical inner ring and outer ring (components can conical outer ring) apart installation.

Taper roller bearings are widely used in automobiles, rolling mill, mining, metallurgical, plastic machinery, etc.

Taper roller bearings which mainly bear with radial primarily diameter, the axial union load. Bearing outer ring rolling bearing capacity depends on the way Angle, the larger Angle bearing capacity is bigger. These bearings are of separated type bearings, according to the roller bearing in the column number to be mounted, double row and four row circular cone roller bearings. Single tapered roller bearing clearance to users in when installation, adjustment, Double row and four row circular cone roller bearings clearance already in product factory according to user requirements are given, not the user to resize.

Taper roller bearings taper inner ring and outer ring have groove, tapered roller are arranged in between. All taper surface projection lines are the same point in bearing axis reunion. This design makes tapered roller bearings specially suitable for composite (bear) radial and axial load. Bearing axial load ability is mostly decided by the contact Angle is alpha, Alpha greater perspective, axial load capacity is higher. Angle size by calculating coefficient e to say, E is, the contact Angle is, the bigger the bearing axial load applicability is greater.

Taper roller bearings are usually separated type, namely the belt roller and maintains a module of the inner ring of conical inner ring and outer ring (components can conical outer ring) apart installation.

Taper roller bearings are widely used in automobiles, rolling mill, mining, metallurgical, plastic machinery, etc.

|

|

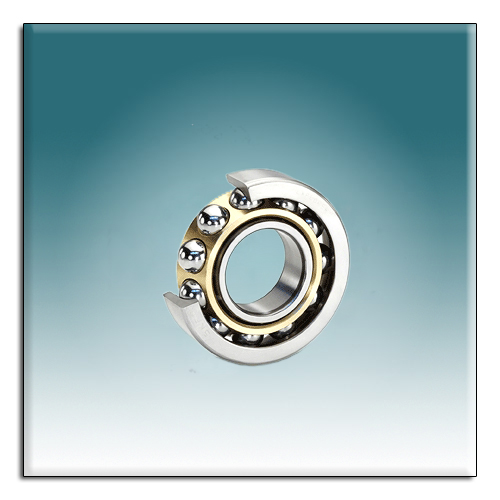

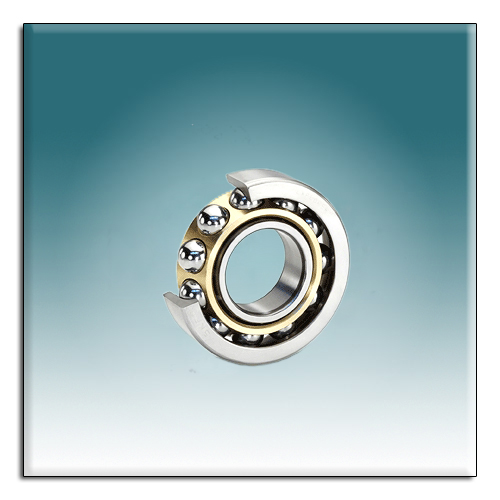

Angle contact ball bearing

Angle contact ball bearing can be both radial load and axial load. Can work under at higher speed. Contact Angle is, the greater the axial bearing capacity is higher. High precision and high-speed bearing usually take 15 degrees contact Angle. Under the action of the axial force, contact Angle increases. Single Angle contact ball bearing can only carry axial load in one direction, in radial load, will cause additional axial force. And only limit shaft or shell in a direction of the axial displacement. If quality.the installation, make a pair of bearings, namely the outer ring relatively wide wide end, narrow face the narrow end face. So we can avoid cause additional axial force in both directions, but also in the shaft or shell limit axial clearance range. Angle contact ball bearing outer ring inside the groove because there can be in a horizontal axis relative displacement, so can both radial load and axial load - union load (single Angle contact ball bearing single direction can only carry axial load, so usually paired often adopted installed). Maintains a material has brass, synthetic resins, the bearings form, in accordance with the using conditions and divisional. Angle contact ball bearing are: 7000C type (∝ = 15 °), 7000AC type (∝ = 25 °) and 7000B ∝ = 40 °) (several types. The bearing outer ring in the lock on the mouth, generally can‘t be separated from internal and external circle and can withstand radial and axial load and a combination of direction of the axial load. Axial load capacity by contact Angle, contact Angle decision is the ability of axial load high. The bearing can restrict shaft or shell in a direction of the axial displacement

Angle contact ball bearing can be both radial load and axial load. Can work under at higher speed. Contact Angle is, the greater the axial bearing capacity is higher. High precision and high-speed bearing usually take 15 degrees contact Angle. Under the action of the axial force, contact Angle increases. Single Angle contact ball bearing can only carry axial load in one direction, in radial load, will cause additional axial force. And only limit shaft or shell in a direction of the axial displacement. If quality.the installation, make a pair of bearings, namely the outer ring relatively wide wide end, narrow face the narrow end face. So we can avoid cause additional axial force in both directions, but also in the shaft or shell limit axial clearance range. Angle contact ball bearing outer ring inside the groove because there can be in a horizontal axis relative displacement, so can both radial load and axial load - union load (single Angle contact ball bearing single direction can only carry axial load, so usually paired often adopted installed). Maintains a material has brass, synthetic resins, the bearings form, in accordance with the using conditions and divisional. Angle contact ball bearing are: 7000C type (∝ = 15 °), 7000AC type (∝ = 25 °) and 7000B ∝ = 40 °) (several types. The bearing outer ring in the lock on the mouth, generally can‘t be separated from internal and external circle and can withstand radial and axial load and a combination of direction of the axial load. Axial load capacity by contact Angle, contact Angle decision is the ability of axial load high. The bearing can restrict shaft or shell in a direction of the axial displacement

|

|

|

|

|

|