Go Into URL |

| |

| |

| |

|

Contact Us |

| WELCOME TO CONTACT US! |

|

|

ABOUT US |

| |

Import Bearing Brand >> NACHI Product List

|

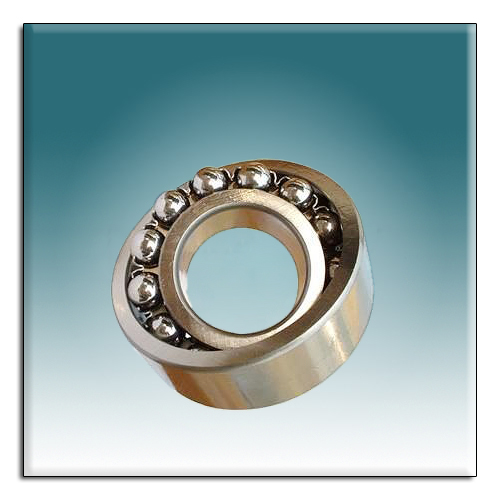

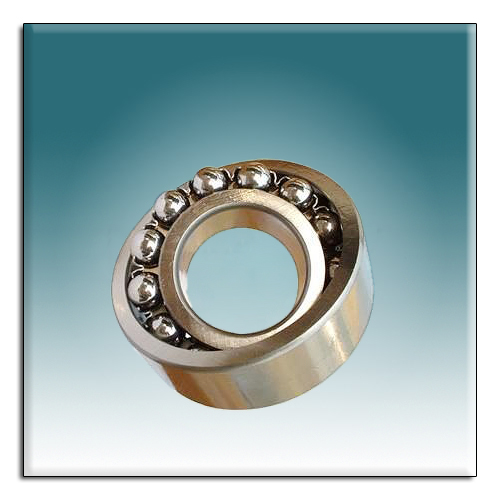

Self-aligning ball bearings

Features: Self-aligning ball bearings with tapered bore cylindrical holes and two structures, cage materials are steel, synthetic resin. Characterized by the outer ring raceway spherical shape, with auto-Mind, can compensate for misalignment and shaft deflection caused by degree of error, but the inner and outer rings relative inclination of not more than 3 degrees.

Point of alignment error on the ability of a regulator. Also has closed and no longer need lubrication design, suitable conditions without maintenance. Installed in the adapter sleeve and within SKF Pillow Block Bearing self-aligning ball bearings are available to customers bearing the economy configuration. 2.1 cylindrical hole aligning ball bearing (10000 type) 2.2 tapered hole aligning ball bearings (1000K type) 2.3 with adapter sleeve aligning ball bearings (1000K + H0000-type).

Self-aligning ball bearing structure in the form: with a dust cover and with a ring of deep groove ball bearing assembly has been filled when the appropriate amount of grease should not be heated before installation do not have to wash, use the process without re-lubrication, to adapt to run temperature between -30 ℃ to +120 ℃.

Because with two bowls and the arc in the outer ring raceway,-aligning ball bearings may be self-aligning, and can withstand the shaft and the bearing angle error between the applicable prone to bending and axial misalignment the working conditions. He has a tapered bore cylindrical holes and two structures, a steel cage materials, synthetic resin. Self-aligning ball bearings Rolling friction is the lowest of all, so even at high speed, it has still only has a smaller temperature rise.

Industrial Applications: Suitable for precision instruments, low noise motors, automobiles, motorcycles and general machinery, the machinery industry, the most widely used class bearings.

Features: Self-aligning ball bearings with tapered bore cylindrical holes and two structures, cage materials are steel, synthetic resin. Characterized by the outer ring raceway spherical shape, with auto-Mind, can compensate for misalignment and shaft deflection caused by degree of error, but the inner and outer rings relative inclination of not more than 3 degrees.

Point of alignment error on the ability of a regulator. Also has closed and no longer need lubrication design, suitable conditions without maintenance. Installed in the adapter sleeve and within SKF Pillow Block Bearing self-aligning ball bearings are available to customers bearing the economy configuration. 2.1 cylindrical hole aligning ball bearing (10000 type) 2.2 tapered hole aligning ball bearings (1000K type) 2.3 with adapter sleeve aligning ball bearings (1000K + H0000-type).

Self-aligning ball bearing structure in the form: with a dust cover and with a ring of deep groove ball bearing assembly has been filled when the appropriate amount of grease should not be heated before installation do not have to wash, use the process without re-lubrication, to adapt to run temperature between -30 ℃ to +120 ℃.

Because with two bowls and the arc in the outer ring raceway,-aligning ball bearings may be self-aligning, and can withstand the shaft and the bearing angle error between the applicable prone to bending and axial misalignment the working conditions. He has a tapered bore cylindrical holes and two structures, a steel cage materials, synthetic resin. Self-aligning ball bearings Rolling friction is the lowest of all, so even at high speed, it has still only has a smaller temperature rise.

Industrial Applications: Suitable for precision instruments, low noise motors, automobiles, motorcycles and general machinery, the machinery industry, the most widely used class bearings.

|

|

Tapered roller bearings

Taper roller bearings which mainly bear with radial primarily diameter, the axial union load. Bearing outer ring rolling bearing capacity depends on the way Angle, greater perspective carrying capacity is bigger. These bearings are separated type bearings, according to belong in the roller bearing the column number to be mounted, double row and four row circular cone roller bearings. Taper roller bearing clearance single user when installation should adjust; Double row and four row circular cone roller bearings clearance has the products leave the factory based on user requirements are given, not the user to resize.

A conical taper roller bearing outer ring groove and inner circle, tapered roller are arranged in between. All the conical surface in bearing axis projection line the same point again. This design makes tapered roller bearing composite (particularly suited to bear radial and axial) load. Bearing axial load ability most is decided by the contact Angle is alpha; Alpha greater perspective, axial load capacity is higher. Angle size by calculating coefficient e to say; E value, the greater the contact Angle, the bigger the axial load bearing the greater the applicability.

Taper roller bearings are usually separated type, namely the belt roller and maintains a component within the cone of circles within circles conical outer components can and outer ring) apart installation (.

Taper roller bearings are widely used in automobiles, rolling mill, mining, metallurgical, plastic machinery, etc.

Taper roller bearings which mainly bear with radial primarily diameter, the axial union load. Bearing outer ring rolling bearing capacity depends on the way Angle, greater perspective carrying capacity is bigger. These bearings are separated type bearings, according to belong in the roller bearing the column number to be mounted, double row and four row circular cone roller bearings. Taper roller bearing clearance single user when installation should adjust; Double row and four row circular cone roller bearings clearance has the products leave the factory based on user requirements are given, not the user to resize.

A conical taper roller bearing outer ring groove and inner circle, tapered roller are arranged in between. All the conical surface in bearing axis projection line the same point again. This design makes tapered roller bearing composite (particularly suited to bear radial and axial) load. Bearing axial load ability most is decided by the contact Angle is alpha; Alpha greater perspective, axial load capacity is higher. Angle size by calculating coefficient e to say; E value, the greater the contact Angle, the bigger the axial load bearing the greater the applicability.

Taper roller bearings are usually separated type, namely the belt roller and maintains a component within the cone of circles within circles conical outer components can and outer ring) apart installation (.

Taper roller bearings are widely used in automobiles, rolling mill, mining, metallurgical, plastic machinery, etc.

|

|

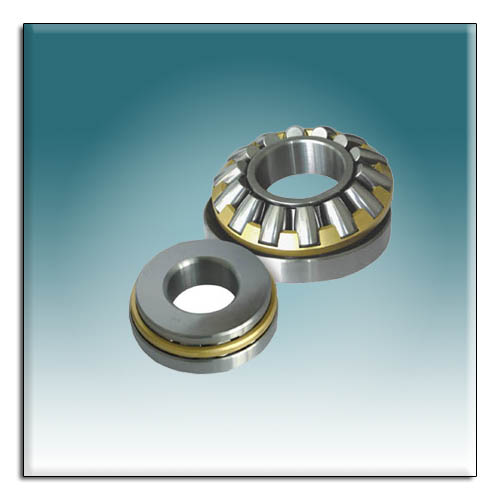

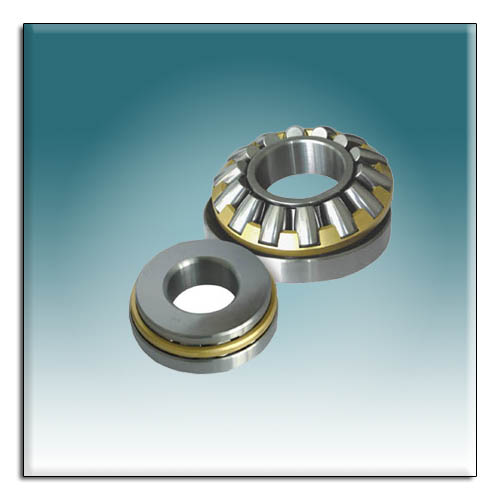

Thrust ball bearings

Thrust ball bearings by a list of steel ball (with keep frame), a shaft circle (and shaft tight fit) and a seat ring (and shaft bearing hole with a gap and a tight fit) composition, steel ball on the shaft lap and seat ring between rotation. Can bear a direction of the axial load, cannot bear radial load. Due to the axial load is evenly distributed in each ball, so load capacity bigger; But work, larger, allowed temperature limit speed is low. Thrust ball bearings can limit the radial shaft or shell, but it can limit moving in the direction of axial and shell a axial movement, thus, such bearing usually and deep groove ball bearing joint use. Thrust ball bearings is separated type bearings, according to its structure form into i.e.one-way thrust ball and two-way thrust ball bearings. I.e.one-way thrust ball bearings can withstand a direction of the axial load, two-way thrust ball bearings can withstand the two directions of the axial load. They are unable to bear radial load. Thrust ball bearing and insert pads structure, due to the installation of seat cushion, so bearing angled spherical shape with self-aligning performance, can reduce the influence of installation error. Thrust ball bearings are used in automobile, machine tools, etc.

Thrust ball bearings by a list of steel ball (with keep frame), a shaft circle (and shaft tight fit) and a seat ring (and shaft bearing hole with a gap and a tight fit) composition, steel ball on the shaft lap and seat ring between rotation. Can bear a direction of the axial load, cannot bear radial load. Due to the axial load is evenly distributed in each ball, so load capacity bigger; But work, larger, allowed temperature limit speed is low. Thrust ball bearings can limit the radial shaft or shell, but it can limit moving in the direction of axial and shell a axial movement, thus, such bearing usually and deep groove ball bearing joint use. Thrust ball bearings is separated type bearings, according to its structure form into i.e.one-way thrust ball and two-way thrust ball bearings. I.e.one-way thrust ball bearings can withstand a direction of the axial load, two-way thrust ball bearings can withstand the two directions of the axial load. They are unable to bear radial load. Thrust ball bearing and insert pads structure, due to the installation of seat cushion, so bearing angled spherical shape with self-aligning performance, can reduce the influence of installation error. Thrust ball bearings are used in automobile, machine tools, etc.

|

|

Thrust roller bearings

Thrust roller bearings are used to carry axial load primarily axial and radial joint load, but shall not exceed the radial load 55% of axial load. Compared with other thrust roller bearings, such bearing friction factor is lower, speed is higher, and have self-aligning performance. 29,000 type bearings‘s stick for the unsymmetrical spherical roller, can reduce roller and groove in the work relative sliding, and roller long, large diameter, roller number, load capacity, high, usually by oil lubrication, individual low-speed grease circumstance is usable.

Thrust roller bearings are used to carry axial load primarily axial and radial joint load, but shall not exceed the radial load 55% of axial load. Compared with other thrust roller bearings, such bearing friction factor is lower, speed is higher, and have self-aligning performance. 29,000 type bearings‘s stick for the unsymmetrical spherical roller, can reduce roller and groove in the work relative sliding, and roller long, large diameter, roller number, load capacity, high, usually by oil lubrication, individual low-speed grease circumstance is usable.

|

|

Deep groove ball bearing

Deep groove ball bearing is the most commonly used rolling bearings. Its simple structure and easy to use. Mainly used to bear radial load, but when increase bearing radial clearance, has certain Angle contact ball bearing performance, can withstand diameter, the axial union load. High in speed and unfavorable use thrust ball bearings, and it can also be used to withstand pure axial load. And the same size as compared with other types of bearings, such bearing small friction coefficient, extreme high speed. But don’t impact resistance, not suitable for under heavy load. Deep groove ball bearing installed in shaft, in bearing axial clearance can restrict, within the scope of the shaft or shell axial displacement two directions, so it can be axial orientation. Two-way In addition, these bearings are still has certain self-aligning ability, when compared with housing holes‘, ’tilt 2 and still ~ 10, but can work normally have certain influence to bearing life. Deep groove ball bearing maintains a more for stamping steel wave shape keep frame, large bearings used more car manufacturing metal entity keep frame. Deep groove ball bearing widely used in automobiles, tractors, machine tools, electric motors, pumps, agricultural machinery, textile, machinery, etc.

Deep groove ball bearing is the most commonly used rolling bearings. Its simple structure and easy to use. Mainly used to bear radial load, but when increase bearing radial clearance, has certain Angle contact ball bearing performance, can withstand diameter, the axial union load. High in speed and unfavorable use thrust ball bearings, and it can also be used to withstand pure axial load. And the same size as compared with other types of bearings, such bearing small friction coefficient, extreme high speed. But don’t impact resistance, not suitable for under heavy load. Deep groove ball bearing installed in shaft, in bearing axial clearance can restrict, within the scope of the shaft or shell axial displacement two directions, so it can be axial orientation. Two-way In addition, these bearings are still has certain self-aligning ability, when compared with housing holes‘, ’tilt 2 and still ~ 10, but can work normally have certain influence to bearing life. Deep groove ball bearing maintains a more for stamping steel wave shape keep frame, large bearings used more car manufacturing metal entity keep frame. Deep groove ball bearing widely used in automobiles, tractors, machine tools, electric motors, pumps, agricultural machinery, textile, machinery, etc.

|

|

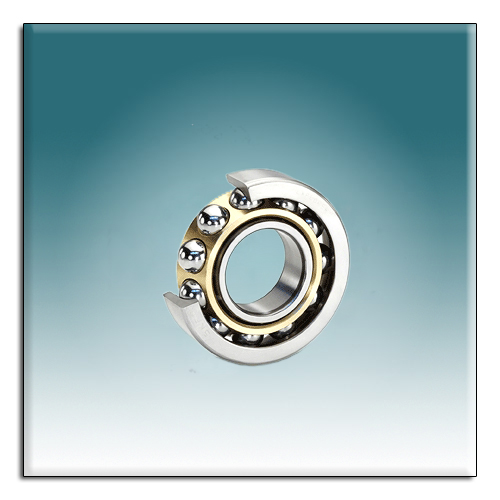

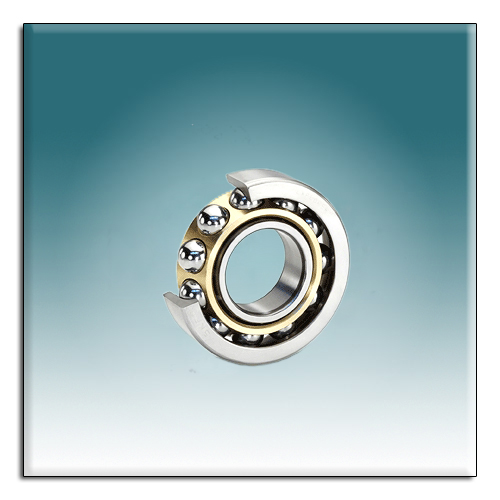

Angle contact ball bearing

Angle contact ball bearing can be both radial load and axial load. Can work under at higher speed. Contact Angle is, the greater the axial bearing capacity is higher. High precision and high-speed bearing usually take 15 degrees contact Angle. Under the action of the axial force, contact Angle increases. Single Angle contact ball bearing can only carry axial load in one direction, in radial load, will cause additional axial force. And only limit shaft or shell in a direction of the axial displacement. If quality.the installation, make a pair of bearings, namely the outer ring relatively wide wide end, narrow face the narrow end face. So we can avoid cause additional axial force in both directions, but also in the shaft or shell limit axial clearance range. Angle contact ball bearing outer ring inside the groove because there can be in a horizontal axis relative displacement, so can both radial load and axial load - union load (single Angle contact ball bearing single direction can only carry axial load, so usually paired often adopted installed). Maintains a material has brass, synthetic resins, the bearings form, in accordance with the using conditions and divisional. Angle contact ball bearing are: 7000C type (∝ = 15 °), 7000AC type (∝ = 25 °) and 7000B ∝ = 40 °) (several types. The bearing outer ring in the lock on the mouth, generally can‘t be separated from internal and external circle and can withstand radial and axial load and a combination of direction of the axial load. Axial load capacity by contact Angle, contact Angle decision is the ability of axial load high. The bearing can restrict shaft or shell in a direction of the axial displacement.

Angle contact ball bearing can be both radial load and axial load. Can work under at higher speed. Contact Angle is, the greater the axial bearing capacity is higher. High precision and high-speed bearing usually take 15 degrees contact Angle. Under the action of the axial force, contact Angle increases. Single Angle contact ball bearing can only carry axial load in one direction, in radial load, will cause additional axial force. And only limit shaft or shell in a direction of the axial displacement. If quality.the installation, make a pair of bearings, namely the outer ring relatively wide wide end, narrow face the narrow end face. So we can avoid cause additional axial force in both directions, but also in the shaft or shell limit axial clearance range. Angle contact ball bearing outer ring inside the groove because there can be in a horizontal axis relative displacement, so can both radial load and axial load - union load (single Angle contact ball bearing single direction can only carry axial load, so usually paired often adopted installed). Maintains a material has brass, synthetic resins, the bearings form, in accordance with the using conditions and divisional. Angle contact ball bearing are: 7000C type (∝ = 15 °), 7000AC type (∝ = 25 °) and 7000B ∝ = 40 °) (several types. The bearing outer ring in the lock on the mouth, generally can‘t be separated from internal and external circle and can withstand radial and axial load and a combination of direction of the axial load. Axial load capacity by contact Angle, contact Angle decision is the ability of axial load high. The bearing can restrict shaft or shell in a direction of the axial displacement.

|

|

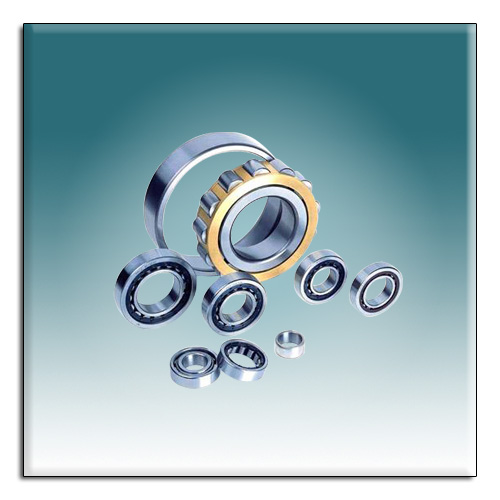

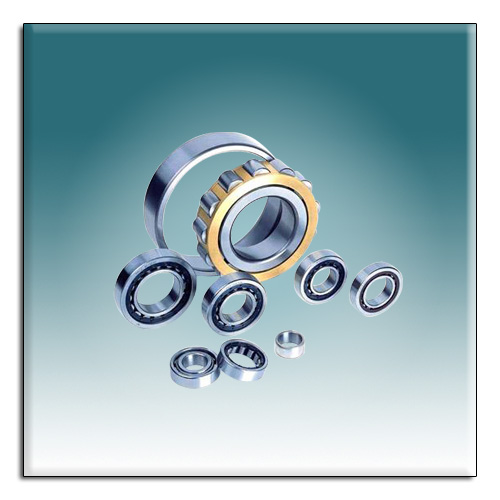

Cylindrical roller bearing

Cylindrical roller bearing genera, separated type bearings and snuck. Cylindrical roller bearing be mounted, double row and four columns. According to the roller bearing outfit column number with different, cylindrical roler bearings can be divided into separate, double row and multicolumn cylindrical roller bearing. Among them are widely applied to keep the aircraft single cylindrical roller bearings. In addition, still with single or double row of other structures installed roller cylindrical roller bearing. According to single cylindrical roller bearing collar divided into raised edge of n-type, NU type, floatation type, NF type and NUP type, etc. Cylindrical roller bearing radial direction load capacity, according to the structure also raised edge collar we can withstand the one-way or two-way axial load. NN by type and NNU type double row cylindrical roller bearing compact structure, strong rigidity, load carrying capacity, distortion, mostly for spindle support. FC, FCDP type FCD, four row cylindrical roler bearings may withstand the big radial direction load, more for mill, etc. heavy machinery. Cylindrical roller bearing is mainly used in motor, machine tool, oil, mill loading/unloading machine and all kinds of industrial machinery.

Cylindrical roller bearing genera, separated type bearings and snuck. Cylindrical roller bearing be mounted, double row and four columns. According to the roller bearing outfit column number with different, cylindrical roler bearings can be divided into separate, double row and multicolumn cylindrical roller bearing. Among them are widely applied to keep the aircraft single cylindrical roller bearings. In addition, still with single or double row of other structures installed roller cylindrical roller bearing. According to single cylindrical roller bearing collar divided into raised edge of n-type, NU type, floatation type, NF type and NUP type, etc. Cylindrical roller bearing radial direction load capacity, according to the structure also raised edge collar we can withstand the one-way or two-way axial load. NN by type and NNU type double row cylindrical roller bearing compact structure, strong rigidity, load carrying capacity, distortion, mostly for spindle support. FC, FCDP type FCD, four row cylindrical roler bearings may withstand the big radial direction load, more for mill, etc. heavy machinery. Cylindrical roller bearing is mainly used in motor, machine tool, oil, mill loading/unloading machine and all kinds of industrial machinery.

|

|

Joint bearing

Joint bearing is a kind of special structure of sliding bearings. Its structure than rolling bearing simple, its main is by a spherical outside of the inner ring and outer ring inside the ball with a composed, can bear larger load, according to its different type and structure, can bear radial load, axial load or radial, axial and existing joint load. Generally used to speed the lower swing motion (namely Angle motion), with the sliding surface, also can be for spherical shape within the scope of certain Angle for tilt movement (i.e. self-aligning movement), in the axis and shaft shell holes concentricity bigger when, still can work normally. Joint bearing is a kind of special structure of sliding bearings.

Joint bearing is a kind of special structure of sliding bearings. Its structure than rolling bearing simple, its main is by a spherical outside of the inner ring and outer ring inside the ball with a composed, can bear larger load, according to its different type and structure, can bear radial load, axial load or radial, axial and existing joint load. Generally used to speed the lower swing motion (namely Angle motion), with the sliding surface, also can be for spherical shape within the scope of certain Angle for tilt movement (i.e. self-aligning movement), in the axis and shaft shell holes concentricity bigger when, still can work normally. Joint bearing is a kind of special structure of sliding bearings.

|

|

Four-point contact ball bearing

Four-point contact ball bearing is radial single Angle contact ball bearing, the design of groove used to support action in two direction of axial load. The bearing can withstand a maximum of axial load one of the few minutes the radial load. This bearing, compared with double row bearing axial space occupied to decline significantly. QJ design SKF four-point contact ball bearing the contact Angle for 35 ° or 45 °. Inner circle ensured inner circle. This allows in bearing load more in the number of ball, thus giving bearing higher load to bear ability. Bearings for separate design, namely take ball and maintains a module can be the outer circle of inner ring with two half were installed.

Four-point contact ball bearing is radial single Angle contact ball bearing, the design of groove used to support action in two direction of axial load. The bearing can withstand a maximum of axial load one of the few minutes the radial load. This bearing, compared with double row bearing axial space occupied to decline significantly. QJ design SKF four-point contact ball bearing the contact Angle for 35 ° or 45 °. Inner circle ensured inner circle. This allows in bearing load more in the number of ball, thus giving bearing higher load to bear ability. Bearings for separate design, namely take ball and maintains a module can be the outer circle of inner ring with two half were installed.

|

|

Water pump bearing

Water pump bearing is in use of bearings, but minimum range of bearing cannot ignore brand. Water pump bearing can use direct drive, bearing body component structure strength, high pump shaft is large in diameter, rigid big cantilever short, in bad condition not bending and vibration. Bearing selecting heavy single circular cone roller bearings, double row circular cone roller bearings to withstand pump of axial and radial load. Bearing is lubricated by grease. Bearing body ends in a bearing gland sealing ring, can effectively prevent the pulp enter and lubrication ester, ensuring safe operation self-clean. Bearing But according to user requirements, bearing transmission parts adopt open, with thin oil for lubrication, reducing axle temperature. The role of MiFengGai pump bearing is to prevent contaminants like dust or cooling water vapor and prevent lubricant spillover. As part of the sealing lip lubricant, which usually have a small amount of oil spill MiFengGai. This volume should not exceed 0.2 g. MiFengGai performance by material and lip black machine decision.

Water pump bearing is in use of bearings, but minimum range of bearing cannot ignore brand. Water pump bearing can use direct drive, bearing body component structure strength, high pump shaft is large in diameter, rigid big cantilever short, in bad condition not bending and vibration. Bearing selecting heavy single circular cone roller bearings, double row circular cone roller bearings to withstand pump of axial and radial load. Bearing is lubricated by grease. Bearing body ends in a bearing gland sealing ring, can effectively prevent the pulp enter and lubrication ester, ensuring safe operation self-clean. Bearing But according to user requirements, bearing transmission parts adopt open, with thin oil for lubrication, reducing axle temperature. The role of MiFengGai pump bearing is to prevent contaminants like dust or cooling water vapor and prevent lubricant spillover. As part of the sealing lip lubricant, which usually have a small amount of oil spill MiFengGai. This volume should not exceed 0.2 g. MiFengGai performance by material and lip black machine decision.

|

|

|

|

|

|